VariGLAZE

VariGLAZE Process Steps

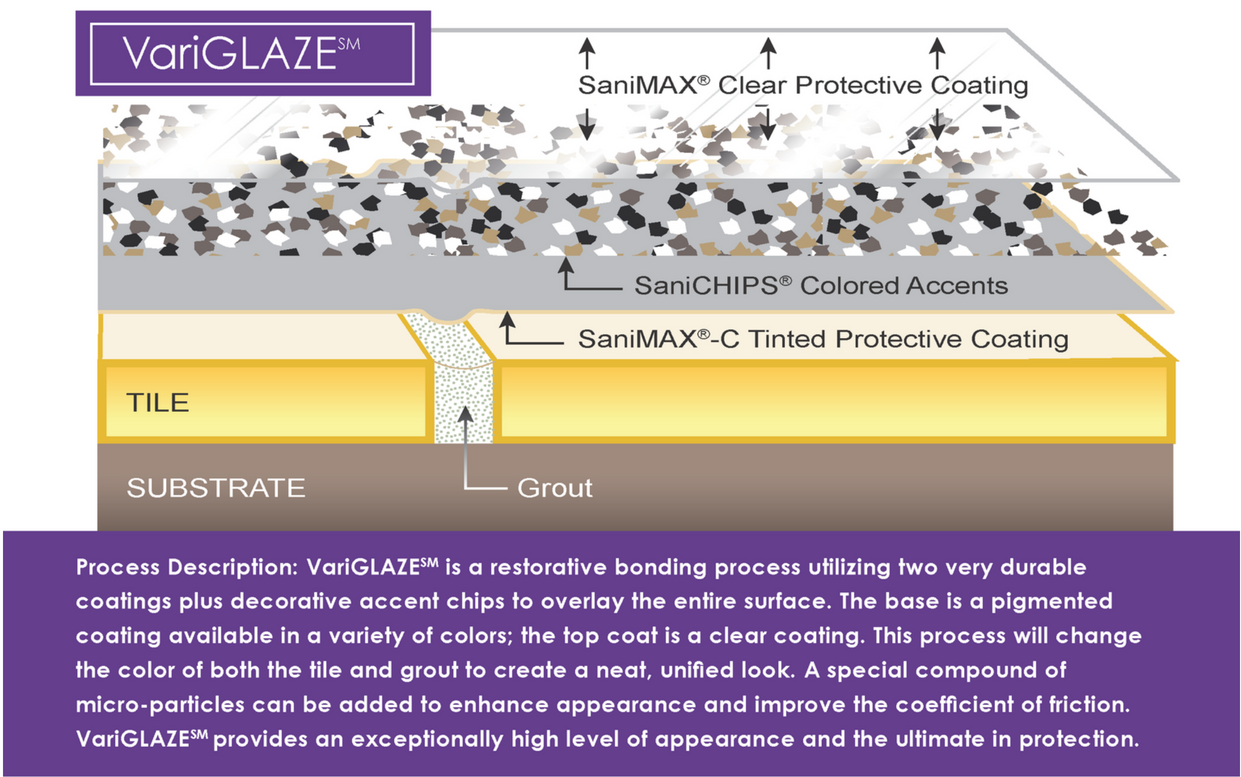

Step 1: Clean and prep entire surface using SaniGLAZE’s XcelKLEEN process to remove contaminants and to prepare tile and grout for

application of SaniGLAZE® coatings.

Step 2: Install SaniMAX-C® protective shield over the entire surface.

Step 3: Apply decorative SaniCHIPS™ over the shield.

Step 4: Install SaniMAX® protective shield over the entire surface.

Primary Products Used

The coatings specified for the EnduraGLAZE Process depend on several factors. Your SaniGLAZE® service professional can advise you on which coatings are best. There are two groups of coatings:

Surface Shield Group:

• SaniMAX-C®: Extremely durable, pigmented topical coating based on the revolutionary new Xolite polymer that is suitable for a wide

variety of tile & grout surfaces. Available in a variety of colors.

• SaniMax®: Extremely durable, clear topical coating based on the revolutionary Xolite polymer that is suitable for a wide variety of tile

& grout surfaces.

• SaniCHIPS™: An array of accent flakes available in various color schemes that are comprised of water-based resin materials and inorganic minerals. They are used to coordinate tile surfaces with any décor.

• Textite®: A compound of micro-particles that can be added to SaniMAX-C® or SaniMAX® to improve the coefficient of friction (COF) and improve appearance. Available in various particle sizes to create the desired COF.

Benefits:

• Restores surface to a brand new appearance

• Prevents soil and moisture penetration

• Eradicates foul odors

• Repels bacteria, mildew and mold

• Simplifies maintenance

• Eliminates expense of replacement

Where and When to Specify:

VariGLAZESM is specified for all tile sizes. It is recommended for surfaces that need a color change, and for situations where an extremely durable coating is required.