GroutGLAZE

GroutGLAZE Process Steps

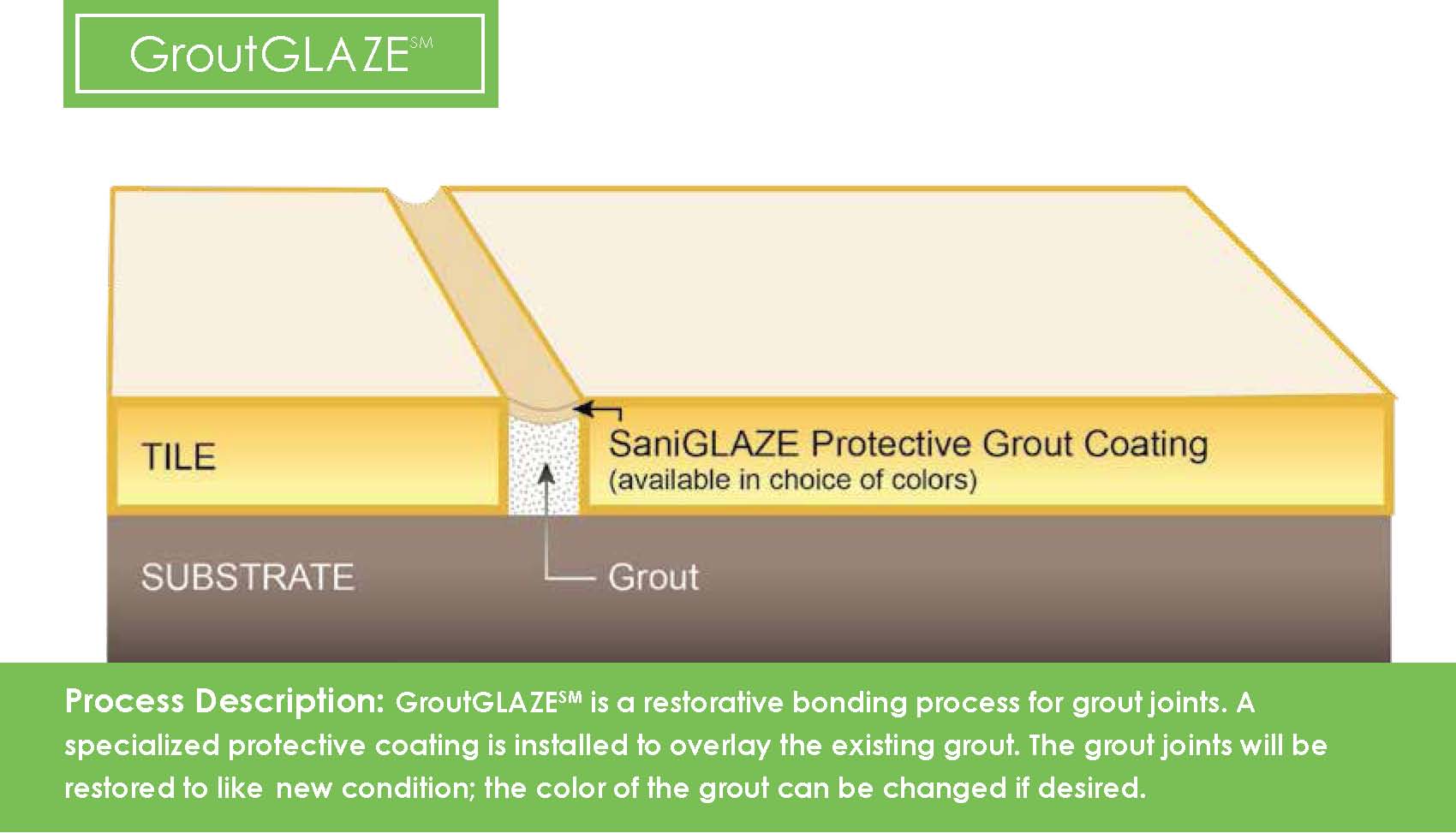

Step 1: clean and prep entire surface using SaniGLAZE’s xcelKLEEn process to remove contaminants and to prepare tile and grout for application of SaniGLAZE® coatings.

Step 2: Install appropriate SaniGLAZE® protective coating over existing grout.

Primary Products Used

The coatings specified for the GroutGLAZESm Process depend on several factors. your SaniGLAZE® service professional can advise you on which coating is best.

Grout Coatings Group:

- SaniKOTE®: opaque armor-like coating available in a wide variety of colors. It is formulated to form-fill, making it ideal for sanded and/or wide grout joints 3/16” or greater in width.

- High Build Glazing Compound®: opaque armor-like coating available in a wide variety of colors. formulated to be more viscous, making it ideal for narrow and/or non-sanded grout joints that are 3/16” or less in width. can be used to raise height of grout joints and to replace missing grout.

Benefits:

• Restores grout joints to like-new

• Prevents grout from soil and moisture penetration

• Eradicates foul odors

• Repels bacteria, mildew and mold

• Simplifies maintenance

• Restores grout joints to like-new

• Prevents grout from soil and moisture penetration

• Eradicates foul odors

• Repels bacteria, mildew and mold

• Simplifies maintenance

Where and When to Specify:

GroutGLAZE is specified for large or small tile sizes. It is recommended where grout joints are in need of restoration, repair or a color change; and where coatings are not recommended for the tile and/or the tile only requires cleaning.